Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:9902

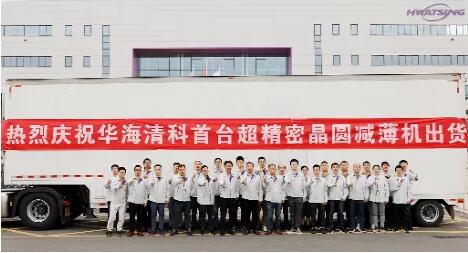

According to the official news of Tsinghua University, recently, the first 12-inch (300mm) ultra-precision wafer thinning machine developed by Huahai Qingke, a Tsinghua University achievement transformation project company led by Professor Lu Xinchun from the Department of Mechanical Engineering of Tsinghua University, has been officially shipped. , sent to a leading domestic integrated circuit enterprise!

This is another breakthrough achievement after the team of Professor Lu Xinchun and Huahai Qingke solved the problem of "stuck neck" of my country's integrated circuit polishing equipment. Precision thinning process requirements.

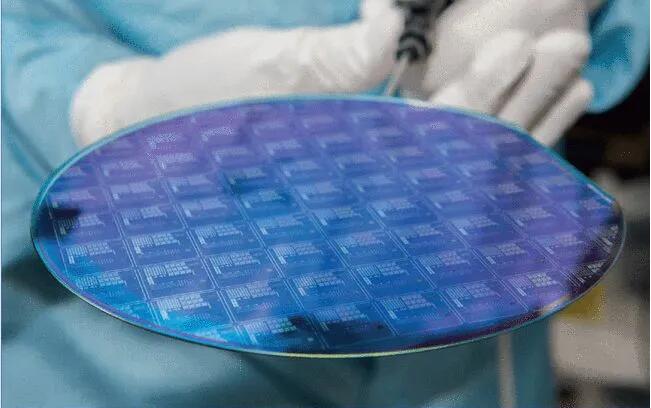

The 12-inch ultra-precision wafer thinning machine is an indispensable key equipment for integrated circuit manufacturing. It is highly complex, difficult to solve technical problems, and has a high market entry threshold. It has been highly monopolized by foreign manufacturers for a long time, and the domestic market is heavily dependent on imports.

In order to break through the technical bottleneck in the field of thinning equipment, Professor Lu Xinchun led Huahai Qingke, using the industrialization experience in the field of chemical mechanical polishing, to focus on research on ultra-precision thinning theory and technology, to overcome ultra-precision grinding of wafer backside, With the core technologies of intelligent flatness control, surface damage and defect control series, the first ultra-precision wafer thinning machine for 12-inch 3D IC manufacturing, advanced packaging and other fields has been developed to solve the problem of "stuck neck" in this field.

Professor Lu Xinchun's team has carried out basic research on chemical mechanical polishing (CMP) since 2000, undertaken more than ten major national scientific and technological tasks, successfully incubated Huahai Qingke, and developed my country's first 12-inch "dry in and dry out" CMP For equipment and series products, the overall technology has reached the international advanced level, the mass production of 28nm process has been achieved, and the 14-7nm process expansion capability has created a number of domestic equipment records.

A total of more than 110 sets of this equipment are used in large production lines of advanced integrated circuit manufacturing, and its market share and import substitution rate are both at the forefront of domestic IC equipment.

The series of achievements filled the domestic gap, broke the monopoly of international giants, and realized the mass industrial application of domestic polishing equipment for the first time.

Professor Lu Xinchun's team also actively promoted the transformation of scientific research results, realized the vertical connection between basic research and industrial demand, and incubated Huahai Qingke, which is currently the only high-end semiconductor equipment manufacturer in my country with a 12-inch CMP commercial model.

Disclaimer: This article is reproduced from "China Semiconductor Forum", this article only represents the author's personal views, not the views of Sac Micro and the industry, only for reprinting and sharing, support To protect intellectual property rights, please indicate the original source and author for reprinting. If there is any infringement, please contact us to delete it.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd