Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:11440

According to Japanese science and technology media reports, AIST has developed a high-speed SiC wafer polishing technology, which can increase the speed by 12 times and greatly reduce the cost. This technology will soon be introduced into the integrated processing technology of 6-inch SiC wafers:

▲ Faster speed: the traditional rotation speed is 50 rpm, and the new technology reaches 700rpm.

▲ Multi-piece polishing: the traditional method can only grind single piece, while the new technology can process multiple pieces at the same time.

▲ Material saving: No grinding fluid is needed, only water is needed.

Speed up 12 times!The polishing cost of high-speed SiC wafer is lowerSome time ago (August), Japan Industrial Technology Research Institute (AIST) announced that they had developed a high-speed polishing technology for SiC wafers. According to reports, the mirror polishing speed of this technology is 12 times faster than before, so it can greatly shorten the processing time of SiC wafer and reduce the cost.

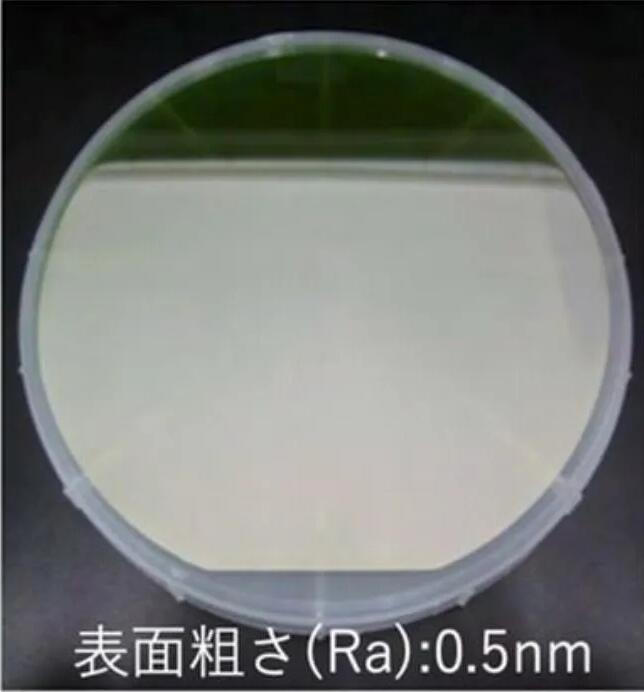

Figure: Appearance of 6-inch silicon carbide wafer polished at high speed.

How does AIST do it?

As SiC wafer is a kind of high-rigidity and brittle material, so far, even if diamond grinding fluid is used for polishing, the grinding speed cannot be increased, because the grinding fluid will generate friction heat. At present, single wafer processing is mainly carried out by grinding until mirror processing (surface roughness Ra≈1 nm) is realized, but the production efficiency is not high.

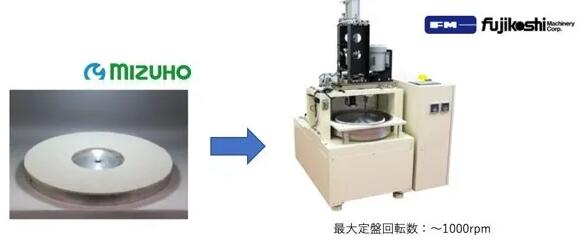

In order to speed up the polishing process, AIST has developed a new SiC wafer polishing technology with Mizuho and Fujitsu Machinery Industry. This technology adopts two kinds of equipment: Mizuho shapes diamond grindstone into a platform, and makes a fixed abrasive platform; At the same time, it combines the high-speed and high-pressure grinding device made by Fujitsu.

Photo: Mizuho's fixed abrasive platform and Fuji Yue's high-speed and high-pressure polishing device.

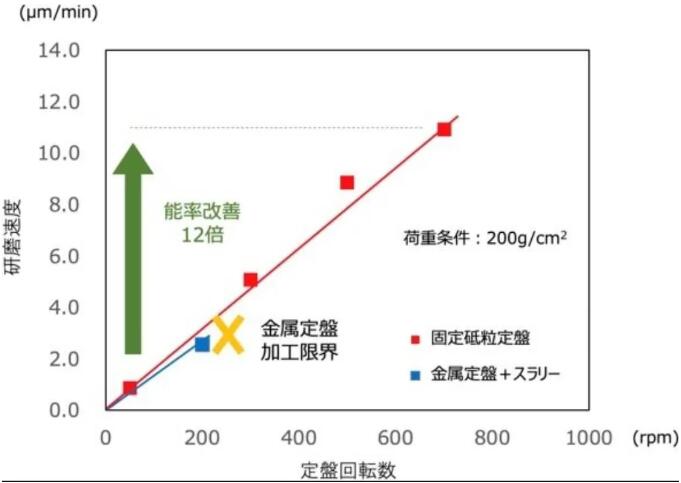

As a result, when a fixed abrasive platform is used, the rotation speed of the platform is proportional to the polishing speed even at 700rpm. Moreover, the polishing speed of the new technology is about 12 times faster than that of the typical processing conditions using grinding fluid (load 200 g/cm2, rotation speed 50 rpm).

At the same time, with the new technology, the Ra of the polished SiC wafer is about 0.5 nm, which achieves the same surface quality as the traditional mirror grinding process. However, in traditional metal platform and slurry processing, the polishing quality will reach the limit when the speed of the platform exceeds 200rpm.

Moreover, unlike the polishing technology using slurry, this high-speed polishing technology only uses water as the treatment liquid, so the environmental load is extremely small. Its other advantage is that it can control the water supply and cooling platform, while ensuring the polishing efficiency.

In addition, because the processing speed is controlled by the processing pressure and the number of revolutions of the platform, it is possible to process multiple SiC wafers at the same time. As a result, high-speed processing and cost reduction can be achieved simultaneously.

What other new technologies are there for SiC?Feiling, Roma, Ansenmei, etc. will be shared soon.

Disclaimer: This article is reproduced from "Wind Trend of the Third Generation Semiconductor". This article only represents the author's personal views, and does not represent the views of Sacco Micro and the industry. It is only for reprinting and sharing to support the protection of intellectual property rights. Please indicate the original source and author when reprinting. If there is any infringement, please contact us to delete it.

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 3518641314 Manager Li

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd