Service hotline

+86 0755-83044319

release time:2022-04-14Author source:SlkorBrowse:14007

Some transistors are over 50 billion in size, and these transistors are 10,000 times smaller than the width of human hair. They are made on the floor of a huge super-clean factory building, which can reach seven stories high and the length is equivalent to four football fields.

Microchips are the lifeblood of modern economy in many ways. They power computers, smart phones, cars, electrical appliances and many other electronic products. However, since the outbreak, the world's demand for them has surged, which has also led to supply chain disruption and global shortage.

This, in turn, has aggravated inflation and aroused people's alarm in the United States: the United States is becoming too dependent on overseas-made chips. The United States accounts for only about 12% of the global semiconductor manufacturing capacity; This, in turn, has aggravated inflation and aroused people's alarm in the United States: the United States is becoming too dependent on overseas-made chips. The United States accounts for only about 12% of the global semiconductor manufacturing capacity;

Intel, the Silicon Valley giant, is trying to restore its long-term leading position in chip manufacturing technology. The company is betting $20 billion, hoping to help alleviate the shortage of chips. The company is building two factories in its chip manufacturing center in Chandler, Arizona, which will take three years to complete. Recently, the company announced a possible larger expansion plan, which will build new factories in New Albany, Ohio and magdeburg, Germany.

Why does manufacturing millions of these tiny parts mean so much to build and spend? Take a look at the Intel manufacturing plants in Chandler and hillsborough, Oregon, and you can find some answers.

What is the function of the chip?

Chip or integrated circuit began to replace the bulky single transistor in the late 1950s. Many of these tiny components are produced on a piece of silicon and connected together to work. The generated chip stores data, amplifies radio signals and performs other operations; Intel is famous for all kinds of microprocessors, which perform most of the computing functions of computers.

Intel has successfully reduced the transistor on its microprocessor to an incredible size. But rival [敏感词] can produce smaller components, which is a key reason why Apple chose [敏感词] to manufacture chips for its latest iphone.

How is the chip made?

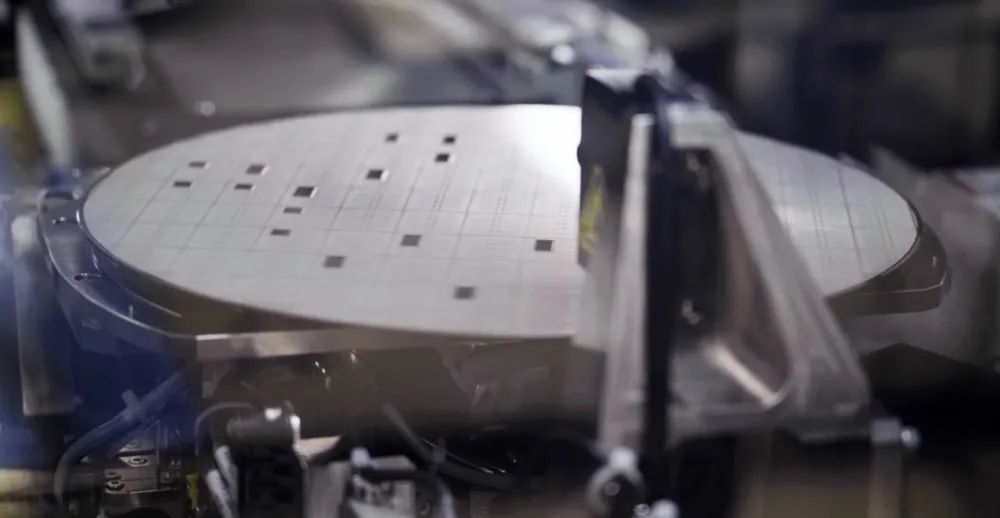

Rows of dedicated machines receive containers full of chips, which are moved in and out of these systems for processing.

One of the machines is used to etch materials from silicon wafers when manufacturing chips.

Chip manufacturers are packing more and more transistors on each piece of silicon, which is why the technology is increasing every year. That's why the new chip factory costs billions of dollars, but few companies can afford it.

In addition to building factories and purchasing machines, companies have to spend huge sums of money to develop complex processing steps and use flat-sized silicon wafers to make chips-that's why these factories are called "fabs".

Huge machines design chips on each wafer, then deposit and etch material layers to make transistors and connect them. In these systems, up to 25 wafers can be transported at a time in a special pod on the automatic elevated track.

Processing a wafer requires thousands of steps, up to two months. In recent years, [敏感词] has set the pace for production, and operates "gigafabs" with four or more production lines. Dan Hutcheson, vice chairman of market research firm TechInsights, estimates that each factory can process more than 100,000 wafers per month. He estimated that Intel's two factories in Arizona, which planned to invest $10 billion, had a monthly production capacity of about 40,000 wafers.

How to package the chip?

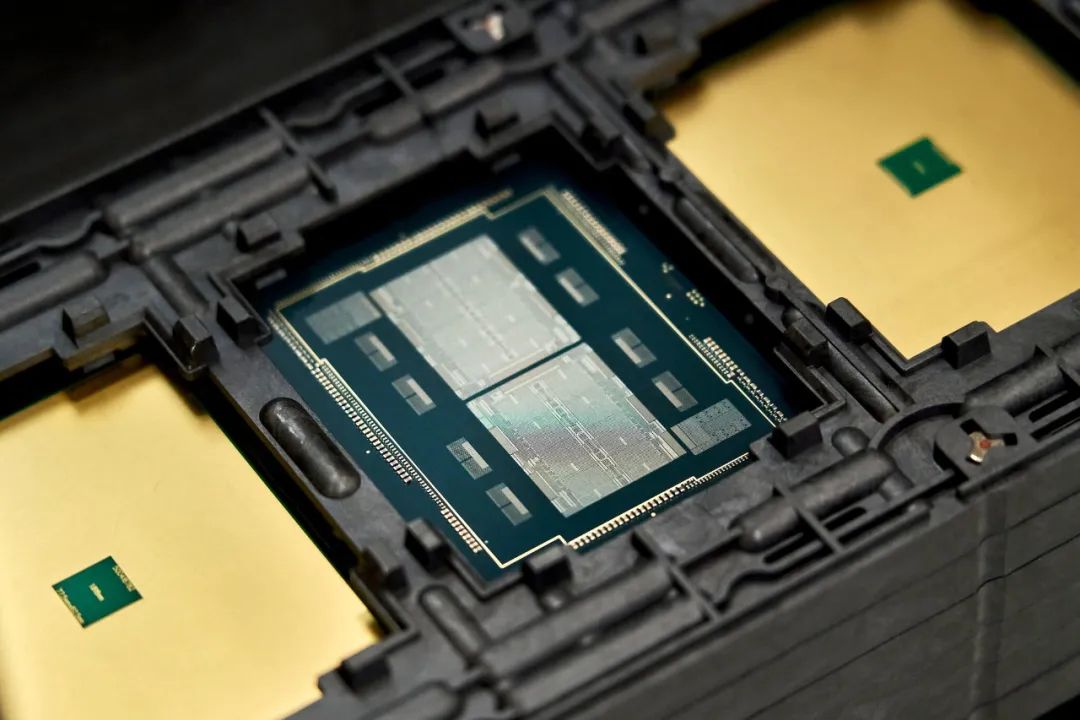

Stack chips with new technology, and then package them.

During the packaging process, small "chiplets" will be directly bonded to the wafer.

During the packaging process, small "chiplets" will be directly bonded to the wafer.

After processing, the wafer is cut into individual slices. These are tested and wrapped in plastic packaging and connected to a circuit board or a part of the system.

This step has become a new battlefield, because it is more difficult to make transistors smaller. Now, companies are stacking multiple chips, or placing them side by side in a package to connect them, just like a silicon chip.

Nowadays, it is a common practice to package a small number of chips together, and Intel has developed an advanced product that uses new technology to bundle 47 independent chips together, including some chips manufactured by [敏感词] and other companies, as well as those produced in Intel factories.

What makes the chip factory different?

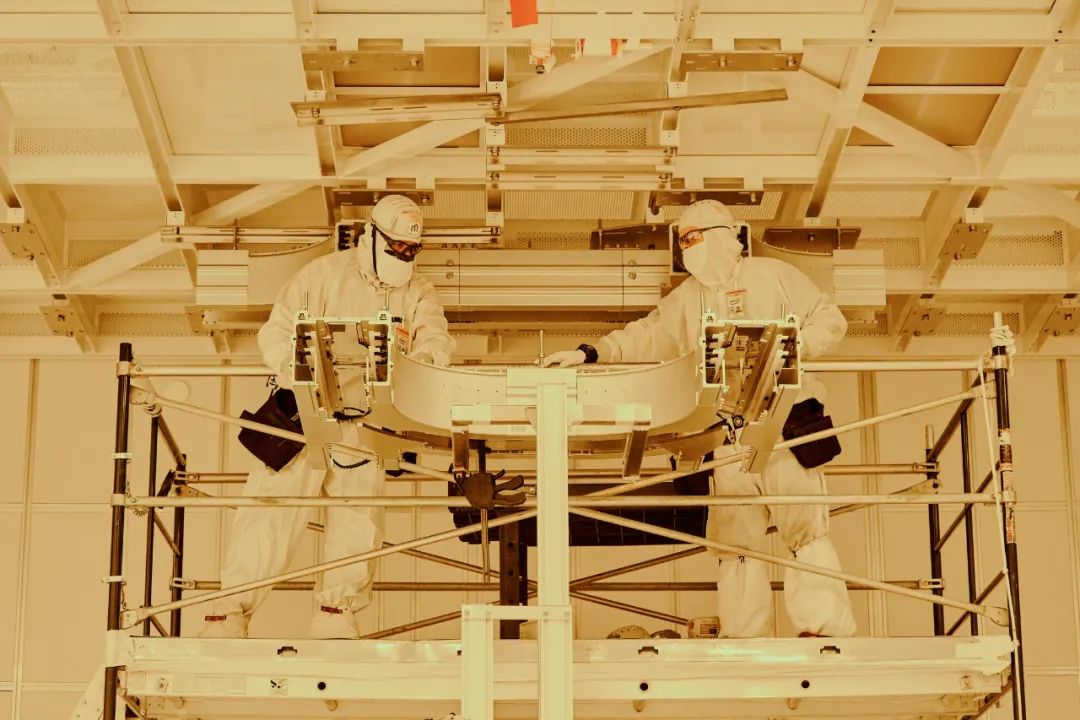

Intel employees wait for moving tool parts in the clean room of the Intel campus in hillsborough, Oregon.

Workers install automatic material handling system in clean room.

Large pipes exhaust gas from processing machines in Intel hillsborough campus.

Intel chips usually sell for hundreds to thousands of dollars. For example, Intel released its fastest desktop computer in March this year.Microprocessor, starting at $739. A piece of invisible dust can destroy a person. Therefore, fabs must be cleaner than hospital operating rooms, and complex systems are needed to filter air and regulate temperature and humidity.Microprocessor, starting at $739. A piece of invisible dust can destroy a person. Therefore, fabs must be cleaner than hospital operating rooms, and complex systems are needed to filter air and regulate temperature and humidity.

The fab must also be free from any vibration that may cause expensive equipment failure. Therefore, the perfect clean room is built on a huge concrete slab and installed on a special shock absorber.

Equally important is the ability to move large amounts of liquids and gases. Intel's top factory is about 70 feet (21 meters) high, with huge fans to help air circulate to the clean room directly below. Below the clean room are thousands of pumps, transformers, power cabinets, utility pipes and chillers connected to production equipment.

The need for water

Water treatment plant in hillsborough. It takes millions of gallons of water every day to make chips.

Intel hopes to cooperate with environmental organizations and other organizations to increase the water supply in Arizona by 2030.

A tower in Intel factory in hillsborough removes gas from water.

Wafer factory is a water-intensive business. This is because water is needed to clean the wafer at many stages of the production process.

Intel's two sites in Chandler draw about 11 million gallons (about 42 million liters) of water from local utilities every day. Intel's future expansion will require more funds, which seems to be a challenge for a drought-stricken state like Arizona, which has cut its water allocation to farmers. But agriculture actually consumes much more water than a chip factory.

Intel said that its site in Chandler relied on the supply of three rivers and one well, and recovered about 82% of fresh water through filtration system, sedimentation tank and other equipment. The water was sent back to the city, which operated Intel-funded treatment facilities and redistributed it for irrigation and other non-drinking water uses.

Intel hopes to promote water supply in Arizona and other states by 2030 through cooperation with environmental protection organizations and other organizations on projects of saving and restoring water resources in local communities.

How to build a fab?

Workers in hillsborough carry building materials.

One of Intel's future factories in Chandler. To build its facilities, Intel will need about 5,000 skilled construction workers for three years.

Excavating the foundations of two new factories in Chandler is expected to remove 890,000 cubic yards of soil.

Chandler The excavated soil will be transported away at the speed of a dump truck every minute.

Cranes move building materials at Chandler site. Among other things, these cranes will lift 55 tons of chillers for the new fab.

In order to build the future factory, Intel will need about 5,000 skilled construction workers within three years.

They have a lot of things to do. Dan Doron, Intel's construction director, said that digging the foundation is expected to remove 890,000 cubic yards (about 680,000 cubic meters) of soil, which is transported away at the rate of one dump truck per minute.

The company expects to pour more than 445,000 cubic yards of concrete and use 100,000 tons of steel bars as the foundation, which is more than the steel bars used to build Burj Khalifa, the tallest building in the world.

The company expects to pour more than 445,000 cubic yards of concrete and use 100,000 tons of steel bars as the foundation, which is more than the steel bars used to build Burj Khalifa, the tallest building in the world.

Patrick Gelsinger, who became the CEO of Intel a year ago, is lobbying the U.S. Congress to provide funds for chip factory construction and tax credits for equipment investment. In order to manage the expenditure risk of Intel, he plans to focus on the construction of fabs "shells", which can be equipped with corresponding equipment to cope with market changes.

To solve the problem of chip shortage, Gelsinger will have to carry out his plan to produce chips designed by other companies. But there is only so much a company can do; Products like mobile phones and cars need parts from many suppliers, as well as old chips. In the semiconductor field, no country can be immune. Although promoting the domestic manufacturing industry can reduce the supply risk to some extent, the chip industry will continue to rely on a complex global enterprise network to provide raw materials, production equipment, design software, talents and professional manufacturing.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd