Service hotline

+86 0755-83044319

release time:2023-10-13Author source:SlkorBrowse:15116

Both EUV and DUV lithography machines are highly advanced machines, with high demands for industrial production volume and speed. If every step requires re-alignment, assuming that the lithography machine can only process one die per minute, it would process only slightly over 1000 dies per day, and the factory would run at a loss.

This is something that most people do not understand, and it is easy to underestimate the performance requirements of industrial-grade lithography machines that require fast, automatic, and precise continuous operation.

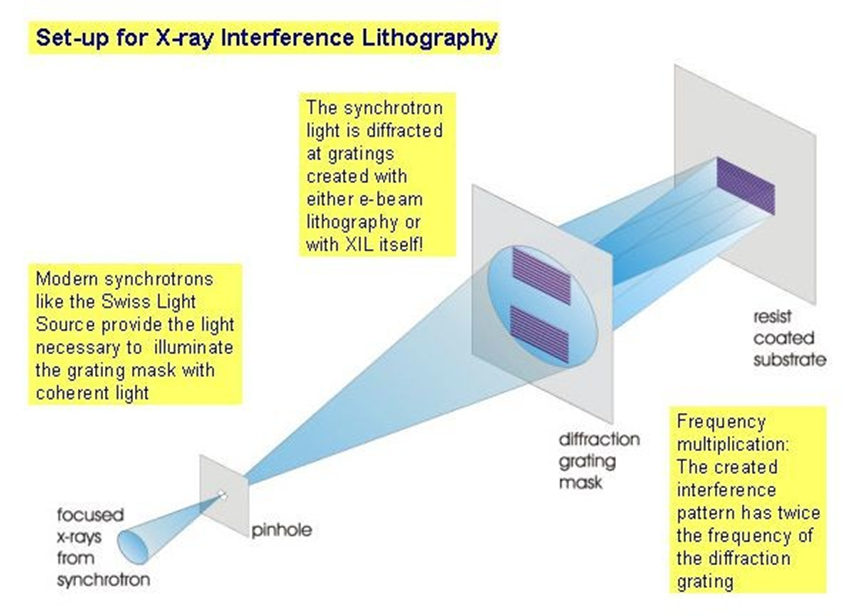

Using EUV light source for chip processing is not a new thing. Researchers have been using EUV light sources from synchrotron accelerators for chip process research since early on, and this has been ongoing with regular publication of papers. For example, the Paul Scherrer Institute has long been exploring new EUV lithography technologies using Switzerland's synchrotron accelerator. In academia, EUV light sources are also referred to as soft X-rays. However, the characteristic of this type of research is not concerned with "mass production" or saving time, but rather slowly making a few chips, measuring some data, and then publishing meaningful discoveries. This is how research was done when there was no EUV light source for industrial applications.

From an industry perspective, the most important thing in the chip industry is engineering application, mass production, and economic viability. As calculated above, this requirement is particularly high, with an incredibly high yield and production speed for mass production. If you don't have a deep understanding of the chip manufacturing process, it's hard to imagine how modern fabs can process and produce vast quantities of chips so quickly.

This is also a process. At the beginning, chips were made by hand or semi-manually, and the yield remained low. In July 1977, Deng Xiaoping and 30 representatives from the scientific and technological community held discussions at the Great Hall of the People. Wang Shouwu, a semiconductor researcher, said: "There are more than 600 semiconductor factories in the country, and the total amount of integrated circuits produced in a year is only one-tenth of the monthly output of a large factory in Japan." This is the difference between manual and automatic processes. Although the gap in the chip process appears small, the difference in manufacturing processes and technological levels behind it is significant.

Now, China can produce 1 billion chips per day, a significant improvement, all achieved through automated machines. Chip manufacturing is inevitably done by machines, and people can only manage them. The machine produces chips, and each process flows very quickly, following the standard assembly-line production mode. The problem with chip FAB production lines is that they are prone to problems and require many skilled personnel to maintain their smooth operation, which is much more difficult than other production lines for other commodities.

To be continued...

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd