Service hotline

+86 0755-83044319

release time:2025-04-21Author source:SlkorBrowse:7344

In the wave of Industry 4.0 and smart manufacturing, industrial equipment's demand for electrical system reliability has entered an era of "zero tolerance." As a key component for protecting against surge voltages, the performance of Transient Voltage Suppression (TVS) diodes directly impacts production line efficiency and equipment lifespan. This article analyzes the technical advantages and application value of the SMF36CA as an example of its role in the new industrial sector.

Slkor Transient Protection Diode SMF36CA product photo

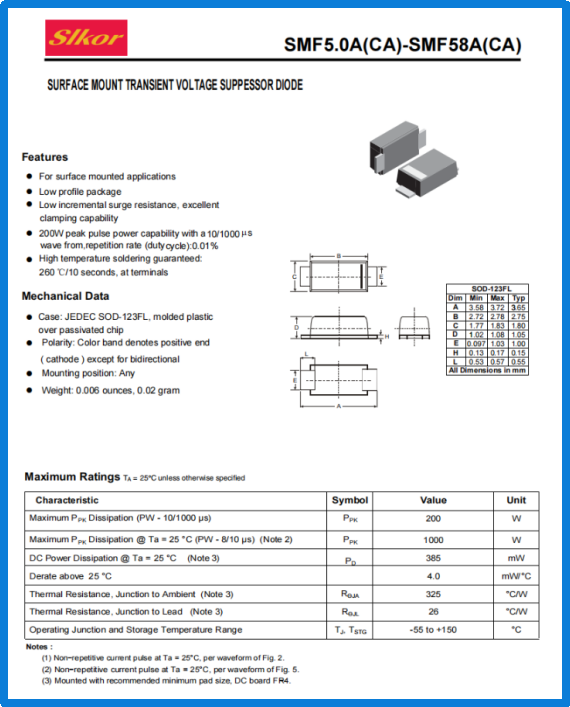

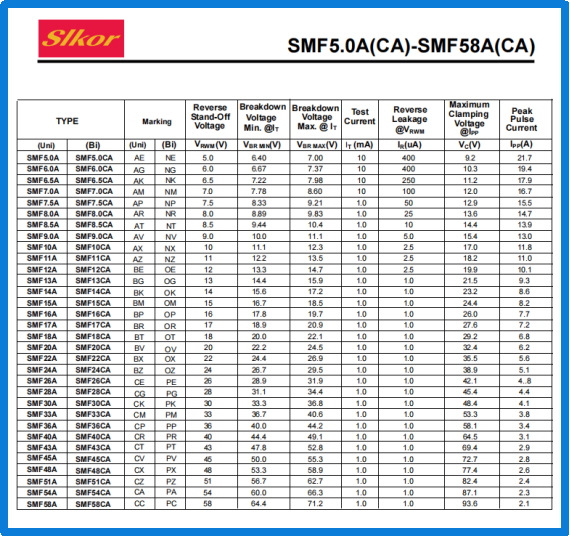

The SMF36CA features an SOD-123FL package, with a 36V reverse standoff voltage and a breakdown voltage range of 40V-44.2V, with a maximum clamping voltage of 58.1V, effectively covering the common 24V-48V power systems found in industrial environments. Its 1.0μA reverse leakage current ensures minimal increase in system power consumption during standby mode, while its 200W peak pulse power (10/1000μs waveform) and 3.44A peak pulse current capability enable it to withstand frequent surge impacts in industrial settings.

Slkor Transient Protection Diode SMF36CA specification

Parameters of Slkor Transient Protection Diode SMF36CA

The protection needs in new industrial scenarios have three key characteristics:

1. Wide Voltage Compatibility: Industrial equipment must support various power sources, including DC supplies, inverter outputs, and solar power.

2. High Frequency Surge Resistance: Motor start-stop cycles, contactor switching, and other operations can cause transient disturbances occurring dozens of times per second.

3. Extreme Environmental Adaptability: Harsh conditions such as high temperatures, humidity, and salt mist impose stringent reliability requirements on components.

The SMF36CA, with its AEC-Q101 automotive-grade certification and industrial-grade temperature range (-55°C to +150°C), perfectly aligns with these demands.

1. Industrial Robot Joint Drives

Industrial robot joint drivers typically use 24V-48V power supplies, and the back EMF generated during motor commutation can exceed 100V. The SMF36CA’s 58.1V clamping voltage safely dissipates surge energy, protecting the driver ICs from damage. Its typical 0.6ns response time (benefiting from the SOD-123FL package) can suppress nanosecond-level spike pulses, ensuring encoder signal integrity.

2. Photovoltaic Inverter DC-Link Protection

During MPPT tracking, the DC bus voltage in photovoltaic inverters can experience instantaneous drops or fluctuations. The SMF36CA’s 36V reverse standoff voltage isolates the DC bus from the control circuit, preventing voltage backfeeding. Its 40V-44.2V breakdown voltage range and 1.0μA leakage current ensure almost no power consumption during standby operation in solar systems.

3. Industrial Ethernet Interface Protection

Industrial Ethernet protocols like Profinet and EtherCAT require zero error-rate signal transmission. The SMF36CA, passing IEC 61000-4-5 (8/20μs waveform) surge testing, combined with its low inductance characteristic (typical value < 1nH), can suppress 10kV contact discharge and 20kV air discharge, ensuring stable data transmission.

The SMF36CA’s breakthrough technology includes:

- Ultra-Low Clamping Voltage Design: By optimizing the chip doping process, the clamping efficiency of the 58.1V clamping voltage is increased by 15%, reducing voltage stress on subsequent circuits compared to similar products.

- High-Temperature Soldering Compatibility: Supports 260°C reflow soldering, meeting the stringent requirements of industrial automation pick-and-place production lines.

- Environmental and Cost Balance: Uses lead-free matte tin plating, complying with RoHS 2.0 standards, and keeps the cost per unit below $0.08.

In Industry 4.0 benchmark projects, the SMF36CA has demonstrated significant value:

- After introducing this component, the failure rate of industrial robot drivers in an automotive manufacturing plant decreased by 42%.

- In photovoltaic power plants, the SMF36CA array design extended the mean time between failures (MTBF) of inverters to over 20 years.

- A food packaging production line reduced PLC downtime caused by surge events by 70% with TVS protection.

As industrial systems evolve towards greater intelligence and connectivity, TVS technology is facing three major development directions:

1. Smart Protection: Integrating surge counting and health monitoring features for preventive maintenance.

2. Integrated Design: Combining TVS with ESD protection, common-mode choke functions, and other components into single-chip solutions.

3. New Energy Adaptation: Developing wide-voltage TVS devices for emerging energy systems like hydrogen and energy storage.

In the new industrial sector, the SMF36CA, with its exceptional transient protection capabilities, creates a strong electrical safety shield for industrial equipment. As technology continues to evolve, this component will play a key role in driving industrial automation toward higher reliability and lower maintenance costs, becoming an indispensable "voltage shield" in the era of smart manufacturing.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd