Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:12880

In the presentation, DENSO stated that the company developed REVOSIC technology aimed at applying SiC power semiconductors (diodes and transistors) to automotive applications. They point out that silicon carbide is a semiconductor material with superior performance in high temperature, high frequency and high pressure environments compared to conventional silicon (Si). Therefore, the use of SiC in critical devices to significantly reduce the power loss, size and weight of systems and accelerate electrification has attracted considerable attention.

In 2014, DENSO introduced a SiC transistor for non-automotive applications and commercialized it for audio products. DENSO continues its research into in-vehicle applications, and in 2018 Toyota used in-vehicle SiC diodes in its Sora fuel cell bus.

Now, DENSO has developed a new automotive SiC transistor, marking the first time DENSO has used SiC for automotive diodes and transistors. The newly developed SiC transistors provide high reliability and high performance in the automotive environment, which presents challenges for semiconductors, thanks to DENSO's unique structure and processing technology, which applies trench gate MOSFETs. The new boost power module equipped with SiC power semiconductors (diodes, transistors) is about 30% smaller in volume and about 70% smaller in power loss than conventional products equipped with Si power semiconductors, contributing to miniaturization. Boost power module to improve vehicle fuel efficiency.

DENSO said that the company will continue to work on the research and development of REVOSIC technology and expand its application to electric vehicles, including hybrid electric vehicles and pure electric vehicles, so as to help build a low-carbon society.

Recently, DENSO pointed out in a press release that power semiconductors are like the muscles of the human body. It moves components like inverters and motors (limbs) based on commands from the ECU (brain). Typical power semiconductors used in automotive products are made of silicon (Si). In contrast, silicon carbide has superior performance in high temperature, high frequency and high voltage environments, helping to significantly reduce inverter power loss, size and weight. Therefore, SiC devices have received attention for their acceleration of vehicle electrification.

Denso pointed out that the boost power module using the company's silicon carbide power semiconductors is about 30% smaller in size and 70% less power loss than conventional products using silicon power semiconductors. This allows for smaller products and improved vehicle fuel efficiency.

Denso engineers also said that compared to silicon, silicon carbide has low resistance, so current flows more easily. Due to this characteristic, a prototype SiC device was damaged by a sudden high current surge. To this end, Denso's multi-department collaboration discussed how to take full advantage of the low-loss performance of SiC while preventing damage to devices on the market, and solved the problem with an idea that our department couldn't come up with alone: using a special driver IC to cut off current at high speed .

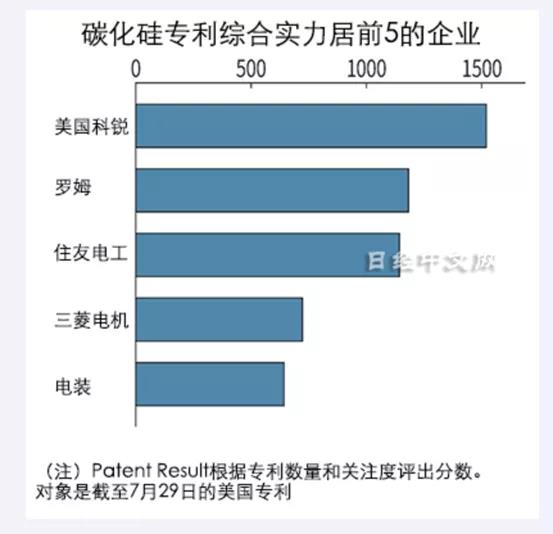

Silicon carbide patent: Denso ranks fifth

According to Nikkei reports, Japanese and American companies have monopolized the top 5 patents related to silicon carbide (SiC), a new-generation semiconductor material. According to the statistics of Japanese Patent Result Company, which is engaged in patent analysis, Cree of the United States, which is involved in silicon carbide semiconductor substrates, ranks first, followed by Japanese companies such as Roma and Sumitomo Electric Industries.

Scores were calculated by volume and attention, based on U.S. patent data released as of July 29. Silicon carbide is used as a substitute for the existing silicon semiconductor substrate material, which contributes to improving the performance and energy saving of power semiconductors. In fields such as pure electric vehicles (EVs) and inverters for photovoltaic power generation systems, the application range of silicon carbide is constantly expanding. In a decarbonized society, demand is expected to expand.

Patent Result's analysis shows that Cree, which ranks first, has advantages in silicon carbide substrates and crystallization patents. No. 2 Roma and No. 5 Denso have advantages in reducing power loss, No. 3 Sumitomo Electric has a stronger crystal structure than silicon carbide, and No. 4 Mitsubishi Electric has an advantage in semiconductor device structure.

DENSO has bigger goals

In 2019, Toyota and Denso jointly announced a new joint venture. The new company mainly develops next-generation automotive semiconductor technology. They set their sights on gallium oxide and diamond, power semiconductors that can challenge SiC (silicon carbide) and GaN (gallium nitride).

Through in-depth research on the basic structure and processing technology of products, the new joint venture will focus on the development of advanced forward-looking technologies for electronic components such as power modules for electric vehicles or peripheral monitoring sensors for autonomous vehicles.

As one of the few OEMs in the world that can produce IGBTs, Toyota has in-depth cooperation with Fuji Electric, Mitsubishi Electric and Denso. Denso, taking a stake in Infineon, cooperates with FLOSFIA, a technology start-up company founded by Kyoto University, to strengthen the development and application of automotive semiconductor products. They are all investing and developing a new generation of power semiconductor devices to reduce and reduce the cost and size of power modules for electric vehicles.

Disclaimer: This article is reproduced from the "Wide Bandgap Semiconductor Technology Innovation Alliance". This article only represents the author's personal views, and does not represent the views of Sac Micro and the industry. It is only for reprinting and sharing, and supports the protection of intellectual property rights. Please indicate when reprinting. The original source and author, if there is any infringement, please contact us to delete it.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd