Service hotline

+86 0755-83044319

release time:2025-04-29Author source:SlkorBrowse:5946

In the design of power systems for industrial robots, mobile service robots, and specialized equipment, transient voltage spikes are a critical challenge threatening system reliability. The SMAJ40A, a transient voltage suppression (TVS) diode optimized for medium to high-voltage scenarios, stands out with its 40V reverse working voltage (Vrwm), 44.4V-49.1V breakdown voltage range, and 64.5V maximum clamping voltage. These features make it an "invisible guardian" for engineers, balancing efficiency and safety in key applications like robotic DC power supply, battery management, and contactless charging. This article, through practical engineering case studies, explores the deep coupling logic between its technical parameters and robotic energy systems.

Slkor Transient Protection Diode SMAJ40A product photo

In the 48V DC power supply systems of industrial robots, AGVs (automated guided vehicles), and other equipment, operations like motor stalling, contactor switching, and power switching can trigger transient overvoltage. The SMAJ40A’s breakdown voltage range (44.4V-49.1V) precisely matches the typical voltage fluctuation range of a 48V system (±10%, or 43.2V-52.8V):

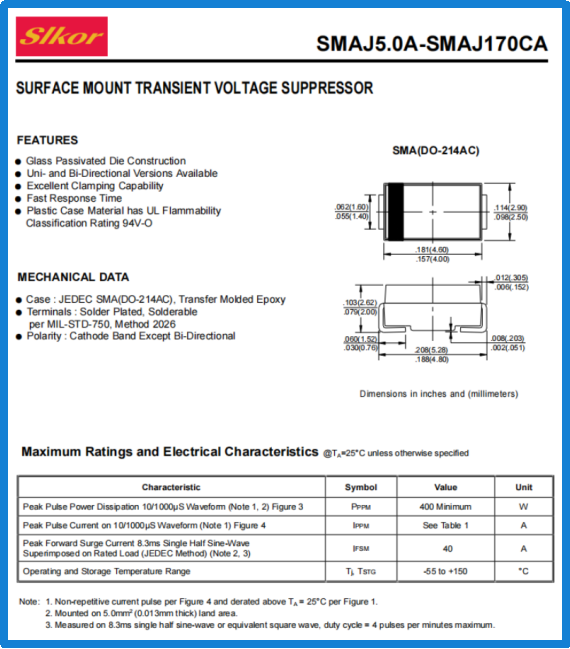

Slkor Transient Protection Diode SMAJ40A specification

Voltage Margin Design: When the system voltage briefly exceeds 44.4V due to a load fluctuation, the SMAJ40A acts before the main fuse, clamping the overvoltage below 64.5V to prevent damage to the main control chip (e.g., NXP’s i.MX 8M series) or power module (e.g., Infineon’s IRF7842 MOSFET).

Parameters of Slkor Transient Protection Diode SMAJ40A

Tiered Protection Strategy: A welding robot production line for the automotive industry uses an “SMAJ40A + fuse” protection scheme: the SMAJ40A absorbs transient pulses in nanoseconds, while the fuse handles sustained overcurrent. Together, they reduced production line downtime from 120 hours to 72 hours per year, lowering annual repair costs by 83,000 RMB.

Thermal Stress Optimization: With a high operating temperature of 150°C and low thermal resistance (θJA≈150°C/W), the SMAJ40A can be directly mounted on the PDU (power distribution unit) PCB without additional heatsinks. In a 3C electronics assembly line, this design reduced the PDU volume by 30% while meeting the 24-hour continuous production requirement.

Outdoor robots (such as photovoltaic inspection and agricultural monitoring robots) often integrate solar or wireless charging modules, which are susceptible to lightning strikes, switching operations, and electromagnetic interference from the environment. The SMAJ40A provides reliable protection through the following mechanisms:

1.Surge Voltage Suppression:

Lightning Protection: In photovoltaic inspection robots, solar panels may experience surges of hundreds of volts due to direct or induced lightning strikes. The SMAJ40A’s 64.5V clamping voltage and 400W (8/20μs pulse) peak power handling capability divert the surge energy to the ground, preventing damage to the charging controller (e.g., MPPT chip). A test in a northwest photovoltaic power station showed that the integration of SMAJ40A reduced the annual lightning failure rate of the robot charging system from 3.2% to 0.45%.

Switching Operation Interference: In wireless charging modules, inverter switching can generate high-frequency overvoltage. The SMAJ40A’s fast response characteristic suppresses interference in the 100kHz-1MHz range, while its ESD protection capability (±30kV, IEC 61000-4-2 standard) further reduces the risk of electrostatic discharge.

2.High-Temperature Environment Adaptation:

Exposure to Sunlight: The SMAJ40A’s 150°C operating capability allows it to be mounted near the robot's top charging interface without concerns about performance degradation due to high summer temperatures. A test in a desert environment showed that after 1000 hours of continuous operation at 70°C ambient temperature, the leakage current increased only to 7μA, with clamping voltage drift of less than 1.5%.

Simplified Thermal Management: Compared to TVS modules that require additional heatsinks, the SMAJ40A’s SMA package (DO-214AC) measures just 3.5mm x 2.1mm and weighs only 0.2g, making robot designs more compact. An agricultural robot using this component reduced the size of its charging module by 40%, while maintaining an IP67 protection rating.

The technical parameters of the SMAJ40A are not standalone; they are deeply integrated with robotic energy systems, transforming into quantifiable engineering value: reducing downtime in DC power supplies, extending cycle life in battery management, and enhancing environmental adaptability in contactless charging. As robot products evolve towards higher voltage (e.g., 80V-100V systems) and higher integration, TVS devices will need to further integrate with power semiconductor technologies (such as SiC-based TVS) and intelligent diagnostic functions (e.g., built-in overvoltage counters). However, their core mission remains unchanged—protecting the safety baseline of robotic energy systems with lower costs and higher efficiency.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd