Service hotline

+86 0755-83044319

release time:2025-04-29Author source:SlkorBrowse:6541

With the rapid development of industrial automation and intelligent service robots, transient voltage suppression diodes (TVS) serve as essential protective components in electronic circuits. Their core value lies not in showcasing technical parameters, but in solving practical engineering issues in robotics R&D, thus tightly connecting with product performance, reliability, and cost control. Taking the SMAJ16A as an example, this surface-mount TVS diode plays an irreplaceable role in circuit protection, energy management, and system integration for robotics products through its 16V reverse working voltage, 26V clamping voltage, and other key features. The following analysis explores the underlying logic of its technical connection from a practical engineering perspective.

Slkor Transient Protection Diode SMAJ16A product photo

Core circuits in robotics products (such as controllers, sensor interfaces, and communication modules) are highly sensitive to transient voltage anomalies. Typical applications of the SMAJ16A include:

1. Industrial Robot Joint Drivers

In welding, spraying, and other scenarios, electromagnetic interference (EMI) generated by motor start/stop can propagate through power lines to the controller. The SMAJ16A limits the overvoltage to below 26V, preventing voltage spikes from damaging the main control chip (e.g., TI’s C2000 series DSP). For instance, a domestic welding robot manufacturer reduced the controller failure rate from 12% to 3.5% by integrating the SMAJ16A in their motor drive module.

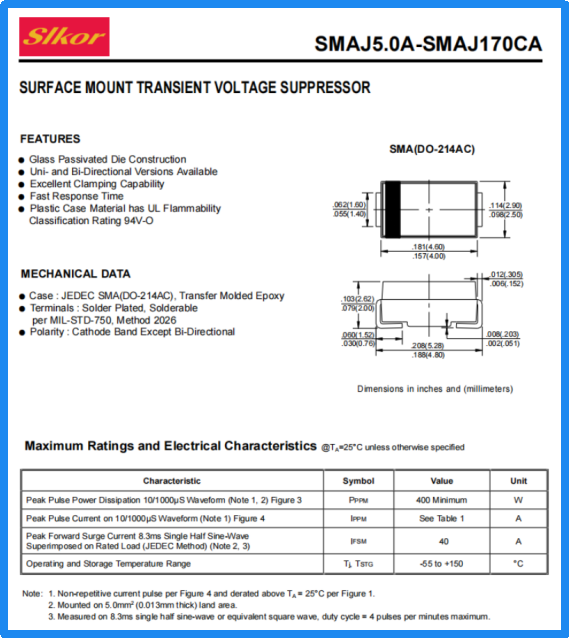

Slkor Transient Protection Diode SMAJ16A specification

2. Collaborative Robot Safety Circuits

In UR-series collaborative robots, the instant a stop button is pressed, back EMF (electromotive force) may occur. The bidirectional protection feature of the SMAJ16A absorbs the reverse current, safeguarding the safety relay and PLC control unit. Its low leakage current of 5μA (at 25°C) ensures that it does not affect battery life during prolonged standby.

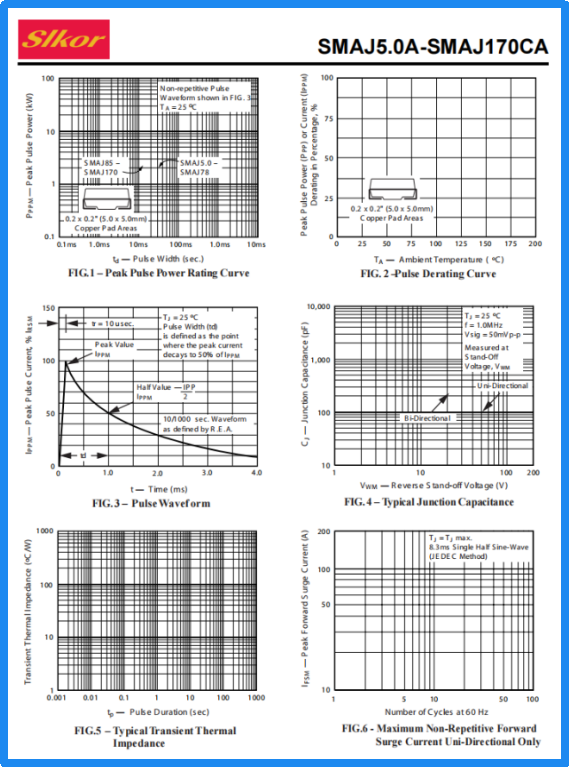

Parameters of Slkor Transient Protection Diode SMAJ16A

3. AGV/AMR Charging Interface Protection

During charging, electrostatic discharge (ESD) generated by plug contact may damage the charging management chip. With its ±30kV ESD protection (according to IEC 61000-4-2), the SMAJ16A, combined with a self-resetting fuse, can create a low-cost yet efficient charging protection circuit. After adopting this solution, a logistics robot company reduced its annual repair costs for the charging module by 60%.

The protective design of robotics products must balance performance, cost, and maintainability. The SMAJ16A integrates into system architecture in the following ways:

1. Modular Protection Design

In robotic control cabinets, a combination of SMAJ16A and TVS arrays (such as SMAJ16CA-TP) can protect individual points and bus overvoltage. For example, a six-axis robotic arm used the SMAJ16A for protection of each joint drive board and the TVS array for CAN bus protection, implementing a tiered protection strategy. This solution increased the system's MTBF (Mean Time Between Failures) threefold, with only a $1.2 material cost increase.

2. Miniaturization and Thermal Optimization

The SMAJ16A has an SMA package (DO-214AC) with a size of only 3.5mm × 2.1mm, making it suitable for compact robot designs. Its low thermal resistance (θJA ≈ 150°C/W) allows direct mounting on the PCB without additional heatsinks. A collaborative robot manufacturer optimized PCB layout by placing the SMAJ16A near the motor driver IC, reducing protection response time by 30%.

3. Fault Diagnosis Interface Design

High-end robotic systems require real-time monitoring of protection devices' status. The SMAJ16A can be paired with voltage monitoring chips (e.g., TI’s INA226) to sample clamping voltage changes via ADC, enabling early warnings and recording of protection actions. A medical robot company adopted this solution, reducing equipment recall costs due to overvoltage by 75%.

The technical parameters of the SMAJ16A must align with the actual requirements of robotics products:

- Voltage Rating: The 16V reverse working voltage is suitable for 24V systems, providing ample safety margin (24V × 1.2 = 28.8V, but considering power ripple, the actual clamping voltage of 26V is safer).

- Power Capacity: With a peak power of 400W (8/20μs pulse), it handles most industrial surges, but larger welding robots may require parallel connections of multiple devices or selection of higher-power models (e.g., SMAJ30CA).

- Environmental Adaptability: The operating temperature range of -65°C to +150°C covers all robotic scenarios, but leakage current may double at low temperatures (10μA at -40°C), requiring assessment of its impact on battery life in battery-powered scenarios.

The choice of parameters, application scenarios, and system integration methods for components like the SMAJ16A must closely follow the specific needs of robotics products. In the future of intelligent equipment development, TVS devices will further integrate with technologies like power semiconductors and digital isolators, forming more efficient and intelligent protection systems.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd