Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:13941

1. Type and structure of MOS tube

MOSFET is a type of FET (the other is JFET), which can be made into enhancement mode or depletion mode, P-channel or N-channel, a total of 4 types, but only the enhancement-mode N-channel MOS is actually used. Tube and enhanced P-channel MOS tube, so NMOS is usually mentioned, or PMOS refers to these two.

As for why not to use depletion-type MOS tubes, it is not recommended to get to the bottom of it.

For these two enhanced MOS tubes, NMOS is more commonly used. The reason is that the on-resistance is small and easy to manufacture. Therefore, in the application of switching power supply and motor drive, NMOS is generally used. In the following introduction, NMOS is mainly used.

There is parasitic capacitance between the three pins of the MOS tube, which is not what we need, but is caused by the limitation of the manufacturing process. The existence of parasitic capacitance makes it more troublesome to design or select the driving circuit, but there is no way to avoid it, which will be described in detail later.

It can be seen on the schematic diagram of the MOS tube that there is a parasitic diode between the drain and the source. This is called the body diode and is very important when driving an inductive load (such as a motor). By the way, the body diode only exists in a single MOS transistor, and usually does not exist inside the integrated circuit chip.

2. MOS tube conduction characteristics

Conduction means acting as a switch, which is equivalent to closing the switch.

According to the characteristics of NMOS, if Vgs is larger than a certain value, it will be turned on. It is suitable for the situation when the source is grounded (low-end drive), as long as the gate voltage reaches 4V or 10V.

The characteristics of PMOS, Vgs is less than a certain value will be turned on, suitable for the situation when the source is connected to VCC (high-end drive). However, although PMOS can be easily used as a high-end drive, NMOS is usually used in high-end drives due to its large on-resistance, high price, and few replacement types.

3. MOS switch tube loss

Whether it is NMOS or PMOS, there is an on-resistance after it is turned on, so that the current will consume energy on this resistance, and this part of the energy consumed is called conduction loss. Selecting a MOS tube with a small on-resistance will reduce the conduction loss. The on-resistance of the current low-power MOS tube is generally around tens of milliohms, and there are also several milliohms.

When MOS is turned on and off, it must not be completed in an instant. The voltage at both ends of the MOS has a falling process, and the flowing current has a rising process. During this time, the loss of the MOS tube is the product of the voltage and the current, which is called switching loss. Usually switching losses are much larger than conduction losses, and the faster the switching frequency, the greater the losses.

The product of the voltage and current at the moment of turn-on is very large, and the loss caused is also very large. Shortening the switching time can reduce the loss at each turn-on; reducing the switching frequency can reduce the number of switching per unit time. Both approaches can reduce switching losses.

4. MOS tube driver

Compared with bipolar transistors, it is generally believed that no current is required to turn on the MOS tube, as long as the GS voltage is higher than a certain value, it is enough. This is easy to do, but we also need speed.

It can be seen in the structure of the MOS tube that there is a parasitic capacitance between GS and GD, and the driving of the MOS tube is actually the charging and discharging of the capacitor. Charging the capacitor requires a current, because the capacitor can be regarded as a short circuit at the moment of charging the capacitor, so the instantaneous current will be relatively large. The first thing to pay attention to when selecting/designing a MOS tube driver is the amount of instantaneous short-circuit current that can be provided.

The second point to note is that the NMOS, which is generally used for high-side driving, needs to be turned on when the gate voltage is greater than the source voltage. The source voltage of the high-side driven MOS transistor is the same as the drain voltage (VCC) when it is turned on, so the gate voltage is 4V or 10V larger than VCC at this time. If in the same system, to get a voltage larger than VCC, a special boost circuit is required. Many motor drivers integrate a charge pump. It should be noted that an appropriate external capacitor should be selected to obtain enough short-circuit current to drive the MOS tube.

The 4V or 10V mentioned above is the turn-on voltage of the commonly used MOS tube, and of course there needs to be a certain margin in the design. And the higher the voltage, the faster the turn-on speed and the smaller the on-resistance. Now there are also MOS tubes with smaller turn-on voltages used in different fields, but in 12V automotive electronic systems, generally 4V conduction is enough.

For the drive circuit of MOS tube and its loss, you can refer to Microchip's AN799MatchingMOSFETDriverstoMOSFETs. It's very detailed, so I don't plan to write more.

5. MOS tube application circuit

The most significant feature of MOS tubes is their good switching characteristics, so they are widely used in circuits that require electronic switches, such as switching power supplies and motor drives.

Analysis of 5 Commonly Used Switching Power Supply MOSFET Driving Circuits

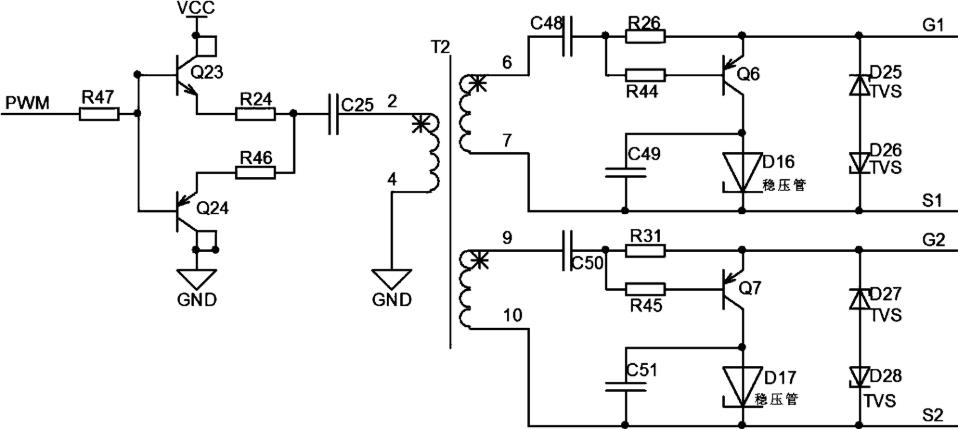

When using MOSFETs to design switching power supplies, most people will consider the on-resistance, maximum voltage, and maximum current of the MOSFET. But in many cases, only these factors are considered. Such a circuit may work normally, but it is not a good design solution. More detailed, MOSFET should also consider its own parasitic parameters. For a certain MOSFET, its driving circuit, the peak current output by the driving pin, the rising rate, etc., will affect the switching performance of the MOSFET.

When the power IC and MOS tube are selected, it is particularly important to select a suitable driving circuit to connect the power IC and the MOS tube.

A good MOSFET driver circuit has the following requirements:

(1) When the switch is turned on, the drive circuit should be able to provide a sufficiently large charging current to rapidly increase the voltage between the gate and source of the MOSFET to the required value, so as to ensure that the switch can be turned on quickly and there is no high-frequency oscillation of the rising edge.

(2) The drive circuit can ensure that the voltage between the gate and the source of the MOSFET remains stable and reliably turned on during the switch-on period.

(3) The drive circuit at the moment of turn-off can provide a path with the lowest possible impedance for the rapid discharge of the capacitor voltage between the gate and the source of the MOSFET, so as to ensure that the switch tube can be turned off quickly.

(4) The structure of the driving circuit is simple and reliable, and the loss is small.

(5) Apply isolation according to the situation.

Do MOS tubes and IGBT drive circuits drive voltage or current?

Both MOS tubes and IDBTs are voltage-driven components. That is, the gate voltage controls the drain or collector current.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd