Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:9691

In harsh or strong electronic interference environment, such as industrial environment and production assembly line, etc., in these systems, mechanical equipment, high frequency

Equipment, spark machine, etc. will produce all kinds of interference and noise, which will affect the normal work of other power supplies. For the requirements of purified power supply, such as the requirements of high quality precision instruments and equipment, especially sensors and weak signal acquisition, DC isolation is adopted.

Power supply is a common and common method.

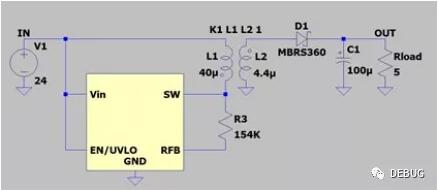

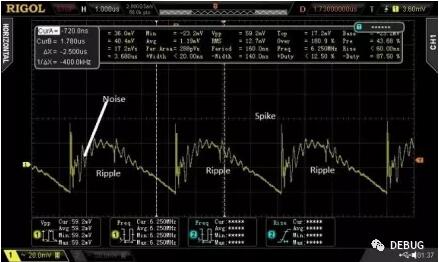

The isolated DC (or noise) power supply is firstly a switching power supply, and ripple and noise are its basic problems. How to effectively reduce ripple and noise is a problem that DC (or noise) isolated power supply must face and solve. This paper analyzes and discusses this problem on the basis of experiments. Fig. 1 is the schematic diagram of a Flyback isolated power supply, and fig. 2 shows the noise test results at 500mA current output.

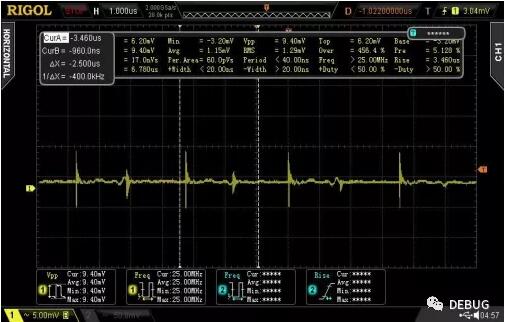

If an AC path is added between two isolated power supplies, it is equivalent to a low-pass filter. Figure 3 shows the noise test results with AC channel. It can be seen from the results that the peak and high frequency noise are reduced.

Figure 3: Noise test with AC path

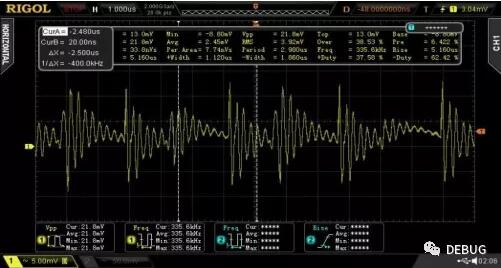

LC low-pass filter is a common and effective method to reduce noise. Although LC can effectively remove and weaken ripple, it will also introduce new noise, which is mainly manifested as high-frequency spikes, and its magnitude is related to output current, LC inductance, parasitic capacitance and so on.

Figure 4: Noise test with LC low-pass filter

Following a linear regulated power supply (LDO) after the switching power supply can also effectively remove and weaken the ripple. Depending on the performance of LDO, it will also introduce new noise. Figure 5.

Figure 5A: Noise test with LDO

Figure 5B: Noise test with LDO and AC path

To sum up, this paper discusses three methods to remove and reduce the noise of isolated switching power supply. Through these methods, we have effectively improved our power products and achieved good results. Power supply is a complex system engineering, which not only involves noise theory, circuit design, electronic measurement, but also depends on PCB layout, wiring and other technological processes, which will not be discussed here.

For most applications, the above methods can basically meet the requirements, such as digital circuits and general analog circuits. However, for higher power supplies such as uV/nA signal measurement, high-precision semiconductor laser power supply and high-precision AD/DA conversion, it is not enough to rely on the above methods. Comprehensive optimization design of various methods can further improve the noise of the power supply.

Figure 6A/B shows the test results of this power supply.Figure 6A Noise Test of Super Low Noise Power Supply [8MHz Bandwidth]

Figure 6B Noise Test of Super Low Noise Power Supply [10Hz-100KHz Bandwidth]

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 3518641314 Manager Li

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd