Service hotline

+86 0755-83044319

release time:2023-10-14Author source:SlkorBrowse:13564

The main process change that affects yield is edge-placement error (EPE). This occurs when unexpected nanoscale irregularities are displayed in the edges and sidewalls of photoresist patterns. These irregularities are random and colloquially referred to as line-edge roughness (LER). As device sizes continue to shrink, LER artifacts can seriously affect dimensional control, and the amplitude of random LER fluctuations begins to compete with circuit pattern tolerances. LER control is critical for improving device performance and manufacturing throughput. LER can be caused by many factors in the processing flow, including errors in lithography and etching steps, as well as nanoscale variations in photoresist chemistry. Therefore, the EUVL industry needs a better understanding of the causes of LER and new tools to mitigate these problems.

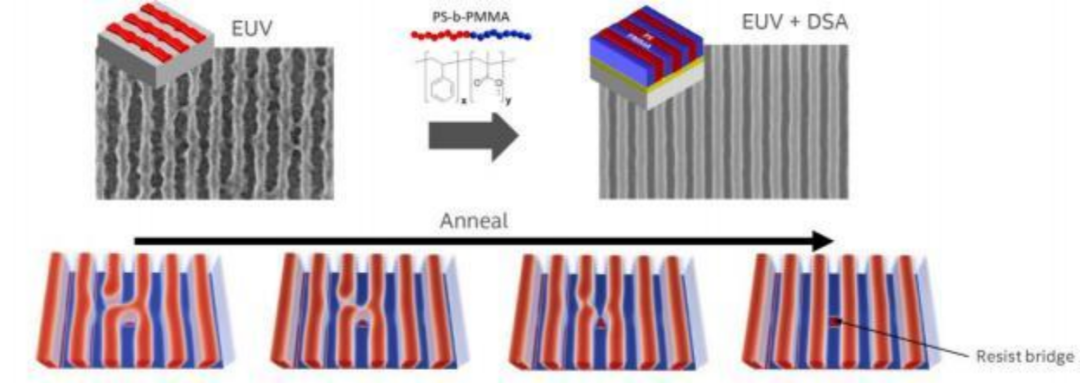

One strategy for reducing errors in line/space anti-etching correction is through directed self-assembly (DSA), as it can remedy defects smaller than the pitch. Figure 9 shows the working principle of EUV+DSA. An industry member of the working group provided a case study on the synergistic combination of EUV, DSA, and self-aligned double patterning (SADP) for 18nm and 21nm metal pitches.

In summary, the key points surrounding EUV photoresist are as follows: scaling down the unit size requires novel process architectures, novel device materials, and reducing interconnect spacing to 12nm. If chip yield is high enough, the cost of EUVL semiconductor chips is primarily limited by productivity (throughput). Yield is mainly determined by random process variations that cause edge placement errors. The metal oxide resist platform exhibits impressive resolution and defect performance at tight pitches, while DSA fundamentally improves systematic and random variations in photoresist.

Lastly, industry participants emphasize that each process change currently requires experimental exploration, with NIST's metrology capabilities and expertise playing a critical role in these activities. Specifically, there are four major subparts to experimental probing of process changes:

(1) Evaluation of process variations among trillions of features, requiring high-throughput methods at a lab scale, possibly like high harmonic generation (HHG) devices discussed in Section 2.5.1.

(2) Chemical formation of random defects in resists, which is an indispensable tool that can be performed in a synchrotron source, discussed in Section 2.5.2.

(3) Detection of process changes at every length scale and increasingly in 3D. Note that this can be achieved through atom probe tomography (APT) techniques, discussed in Section 2.5.3.

(4) At these small length scales, surfaces and interfaces dominate, and sharp interfaces do not exist.

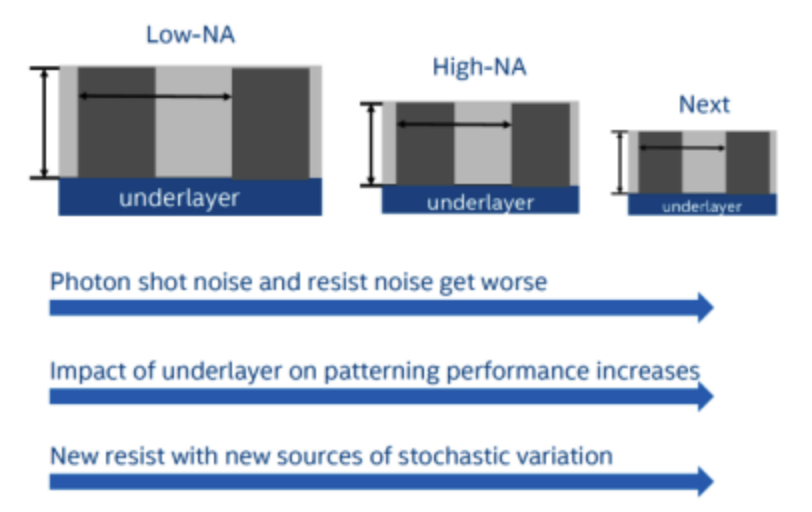

When asked about the outlook and the information industry provides to the research community, NIST provides a list of demands. For photoresists: (a) novel photoresists with higher quantum numbers, (b) origins of photoresist/underlying feature and defect formations, (c) chemical forms of random defects in MOx photoresists, (d) strategies for mitigating photoresist scum, and (e) dry development techniques for organic antireflective coatings. This demand is particularly important as the EUVL manufacturing transitions from low NA to high NA and even higher NA, as shown in Figure 10.

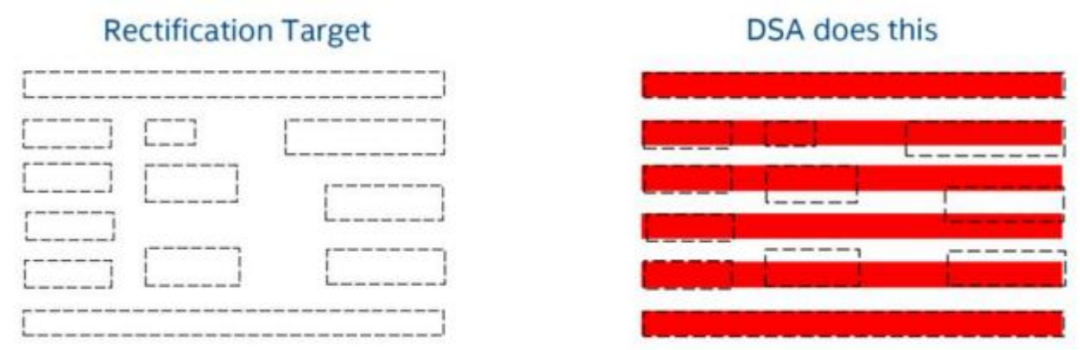

For correction, the industry demands: (a) pitch-independent correction for roughness and defects to preserve target layout, as shown in Figure 11, (b) new DSA molecules with high selectivity dry etching and selective penetration for high gas materials, (c) 3-ton-A-B-C block copolymers, and (d) functional block copolymers and brushes (photo-patternable, cross-linkable, etc.).

2.4.2. EUV Collector Mirrors: Tin Ion, Vapor, and Particle Characterization

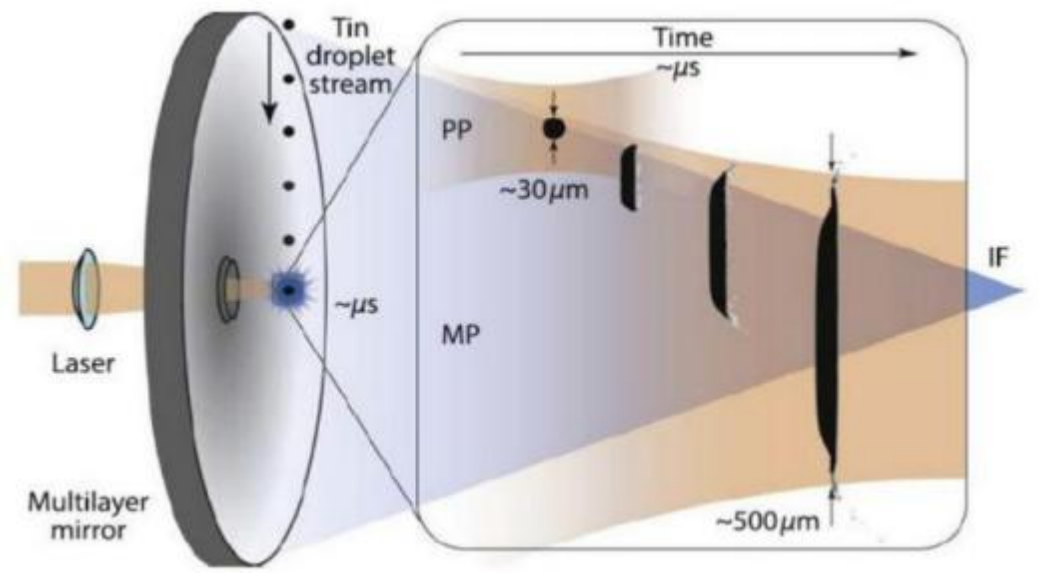

Using EUV light for patterning brings forth many new challenges due to the strong absorption of the 13.5nm radiation by most materials. As a result of this strong material interaction, mirrors instead of lenses are used to generate and guide light in a vacuum. The initial plasma-source collector mirrors are concave and ellipsoidal in shape, with plasma generated at the first focus. At the second or intermediate focus, the plasma light is guided towards the exposure tool (Figure 12). Wavelength matching across the entire collection region and infrared spectral filtration are key features of multilayer collector mirrors.

In addition, generating a sufficient amount of EUV radiation is extremely challenging, so efforts must be made to ensure that the mirrors have the highest possible reflectivity and spatial uniformity. Furthermore, the reflectivity of the multilayer mirrors must be maintained at a high level during the operation of the lithography tool. The lithography process involves exposing patterns on a photoresist, which stores the pattern for further processing (see 2.4.1). EUV radiation causes chemical changes in the photoresist, resulting in volatile compounds that may migrate and adsorb onto surfaces through the vacuum system. Although the photoresist can affect the mirror surface, it is not the main concern for mirror contamination. Industry members have identified two main types of debris that impact the collection mirrors: (1) debris directly from the plasma, with heat and momentum transferred to the surrounding buffer gas H2; and (2) tin flux entering the collector before colliding with any surface, composed of (i) stopping ions, (ii) tin vapor, and (iii) tin particles.

Currently, the method used to protect the collector mirror from debris damage is through a flow of hydrogen gas. A hydrogen gas buffer gas at around 100 Pa causes ion deceleration. Hydrogen flows out of the collector, which reduces the deposition rate of atomic tin on the collector. The reaction between hydrogen radicals and tin forms tin hydride (SnH4), which can be pumped away according to the reaction shown in the equation.

The pumping action that occurs in a container with a vacuum pump removes thermal gases and tin vapor, which also helps protect the collector mirror. Additionally, internal hardware collects particles. The industry has conducted research on cleaning mirrors to address contamination issues. Efforts have been made in the industry to improve the lifespan of collector mirrors, especially with lifespans exceeding 6 months in 2021.

Despite substantial improvements in protecting EUV collector mirrors, industry members have expressed two needs. Firstly, understanding "how photons and plasma materials interact with background gases, optics, and plasma surfaces in an EUV light source." Knowledge gaps include secondary plasma and its interactions, transport and spectroscopy, plasma radiation wall physics and chemistry, and plasma diagnostics. Secondly, understanding "what happens to tin and how to manage it." Knowledge gaps in this area include tin contamination, hydrogen radical cleaning of tin, tin hydride formation processes, as well as associated thermal and mass transfer and chemistry, and small particle detection.

To be continued...

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd